Zero Waste

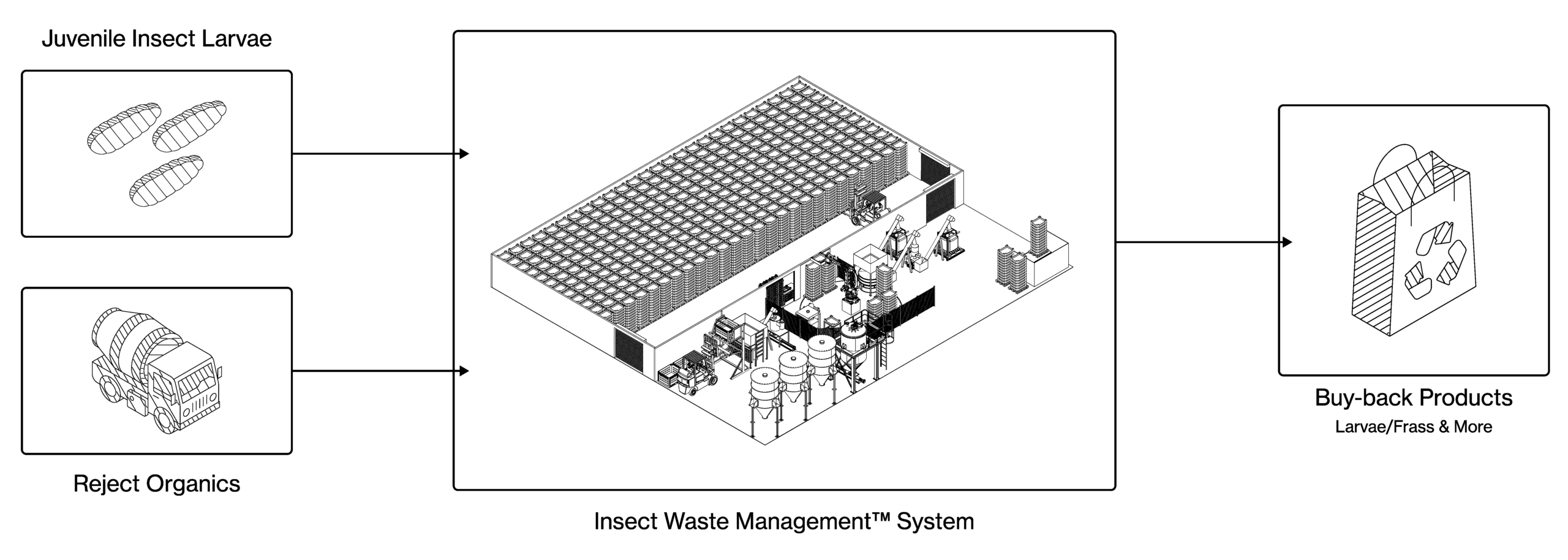

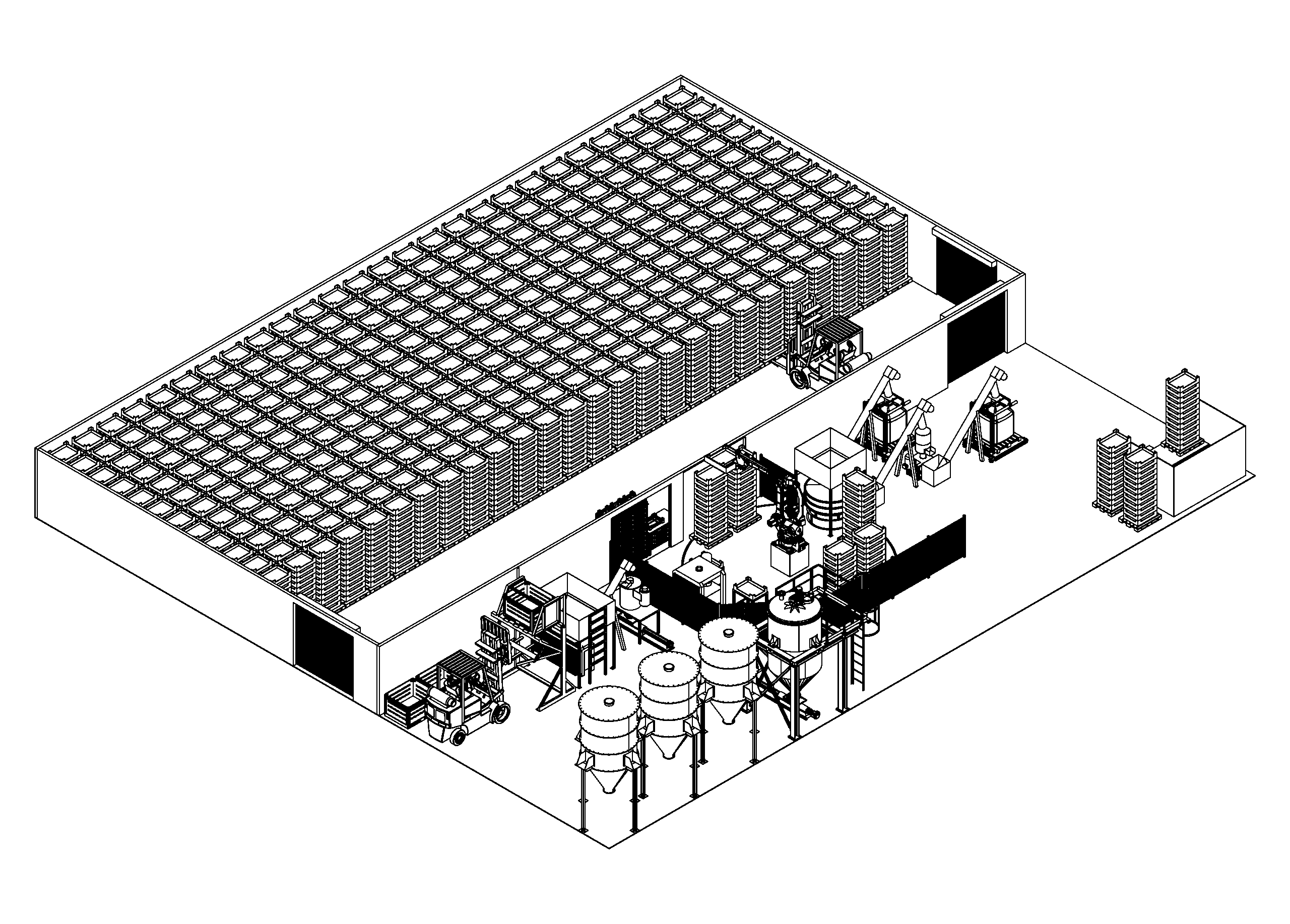

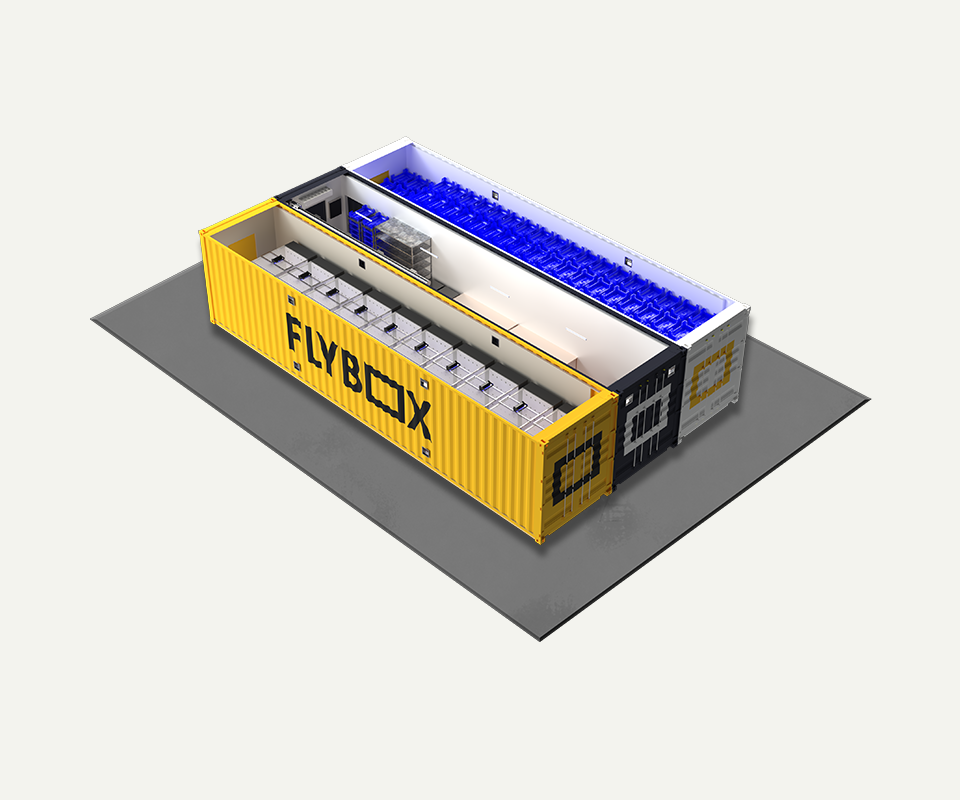

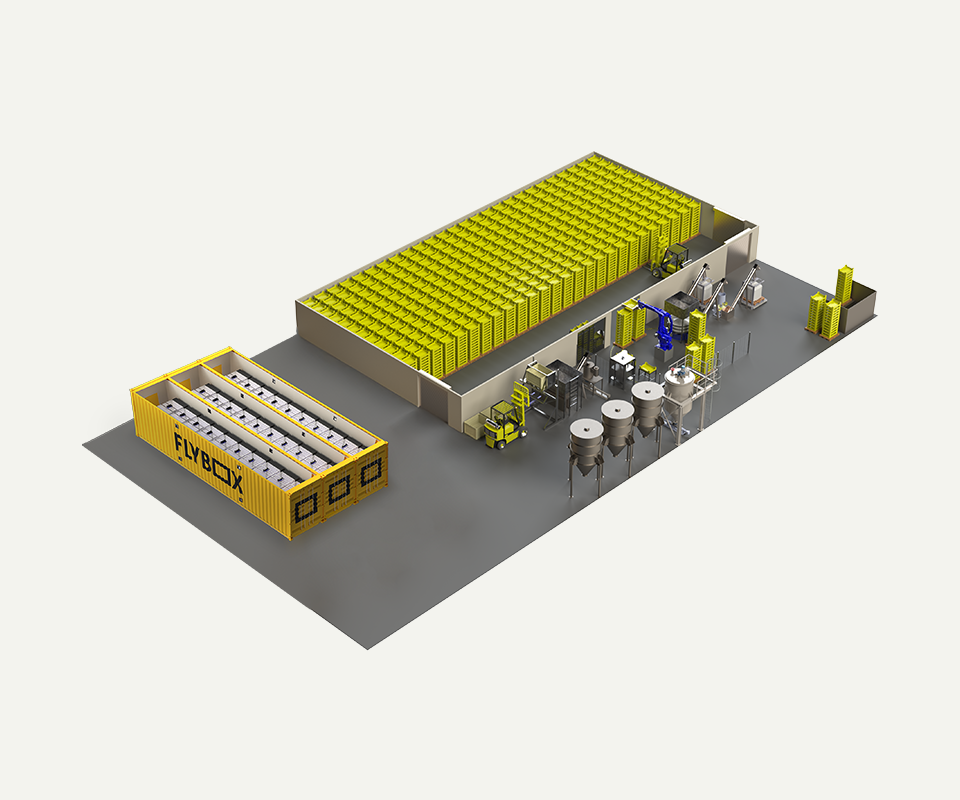

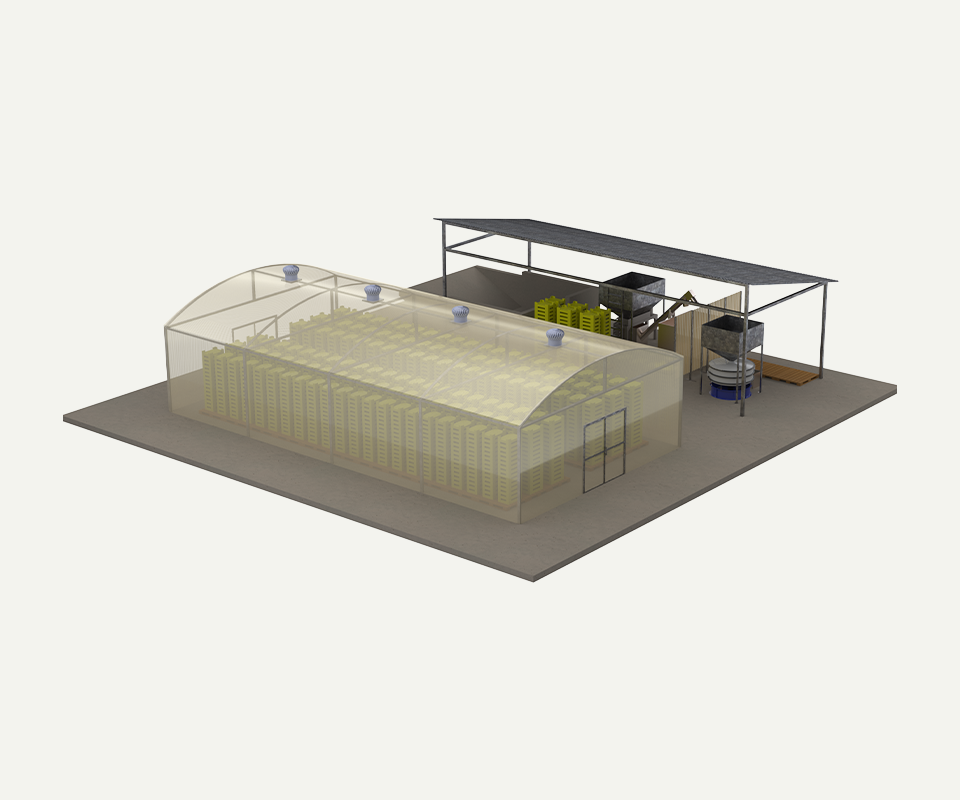

IWM is the most sustainable way to manage reject organics.

Insect bioconversion upcycles reject organics into high-value protein and fertiliser, keeping nutrients in the food system. Waste is reclassified as a byproduct once fed to insects, making your business zero waste.

Read our whitepaper to learn more.

Maximum Profit

IWM is the most profitable way to manage reject organics.

Anaerobic digestion depends on the grid and composting requires significant time. IWM works quickly, operates off-grid, and produces dry, storable byproducts that trade easily in feed and fertiliser markets.

Read our whitepaper to learn more.